DIN7991 Hex Qhov (socket) Countersunk Screw Qib Carbon Steel Zinc Plated Qib 8.8 10.9

DIN7991 Hex Qhov (socket) Countersunk Screw Qib Carbon Steel Zinc Plated Qib 8.8 10.9

Kev piav qhia

QUICKTeb

QUICKNqe lus

QUICKKev xa khoom

NYEEM NTXIV RAU SHIP DELIVERY

10000+ SKU hauv warehouse

Peb cog lus rau RTS cov khoom:

70% cov khoom xa tuaj hauv 5 hnub

80% cov khoom xa tuaj hauv 7 hnub

90% cov khoom xa tuajhauv 10 hnub

Kev txiav txim ntau, thov hu rau cov neeg siv khoom

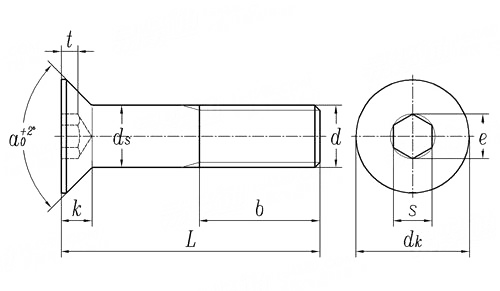

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Suab | 0.5 | 0.7 ua | 0.8 ua | 1 | 1.25 | 1.5 | 1.75 ib | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | xov.(+2) | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 90 ° | 60 ° | 60 ° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L 200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max = Nominal | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 ib | 9.64 ib | 11.57 Nws | 15.57 Nws | 19.48 Nws | 23.48 Nws | 26.48 Nws | 29.48 Nws | 32.38 Nws | 35.38 Nws | 35.38 Nws | 38.38 Nws | |

| ds | Max = Nominal | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 ib | 3.82 ib | 4.82 ib | 5.82 ib | 7.78 ib | 9.78 ib | 11.73 Nws | 13.73 Nws | 15.73 Nws | 17.73 Nws | 19.67 Nws | 21.67 Nws | 23.67 Nws | |

| e | Min | 2.3 | 2.87 ib | 3.44 ib | 4.58 ib | 5.72 ib | 6.86 ib | 9.15 Nws | 11.43 Nws | 11.43 Nws | 13.72 Nws | 13.72 Nws | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Nominal | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 Nws | 2.52 ib | 3.02 Nws | 4.02 ib | 5.02 ib | 6.02 ib | 8.025 ib | 10.025 Nws | 10.025 Nws | 12.032 Nws | 12.032 Nws | 14.032 Nws | 14.032 Nws | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 ib | 6.14 ib | 8.175 ib | 10.175 Nws | 10.175 Nws | 12.212 Nws | 12.212 Nws | 14.212 Nws | 14.212 Nws | |

| t | Max = Nominal | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 ib | 10.3 |

| Min | 0.95 ib | 1.55 ib | 2.05 Nws | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 ib | 9.87 ib | |

Kev piav qhia ntxaws

High zog fasteners yuav ua crispness thaum galvanized. Xav tau kev saib xyuas tshwj xeeb.

Hydrogen embrittlement feem ntau yog tshwm sim los ntawm kev ncua kev puas tsuaj nyob rau hauv kev ntxhov siab. Muaj lub tsheb caij nplooj ntoos hlav, ntxhua khaub ncaws, ntsia hlau, cov ntawv caij nplooj ntoos hlav thiab lwm yam khoom siv galvanized, nyob rau ob peb teev tom qab kev sib dhos tau tawg, qhov tawg ntawm 40% ~ 50%. Nyob rau hauv tus txheej txheem ntawm kev siv cadmium-plated qhov chaw ntawm ib tug tshwj xeeb cov khoom, muaj batch crack fractured, thiab lub teb chaws qhov teeb meem tseem ceeb tau daws thiab ib tug nruj dehydrogenation txheej txheem tau tsim. Tsis tas li ntawd, muaj qee qhov hydrogen embrittlement tsis qhia ncua sij hawm tawg qhov tshwm sim, xws li: electroplating hanger (steel hlau, tooj liab hlau) vim muaj ntau zaus ntawm electroplating thiab pickling plating, hydrogen nkag mus yog hnyav dua, feem ntau tshwm sim nyob rau hauv kev siv lub quav yuav tshwm sim brittle fracture phenomenon; Lub mandrel ntawm rab phom, tom qab ob peb zaug ntawm chroming, poob rau hauv av thiab tawg; Qee qhov quenched (qhov loj hauv kev ntxhov siab) yuav tawg thaum pickling. Cov khoom no yog hydrogenated hnyav heev thiab tawg yam tsis muaj kev ntxhov siab sab nraud, uas tsis tuaj yeem siv los kho qhov qub tawv los ntawm dehydrogenation.

Qhov siab dua cov khoom siv zog, qhov ntau dua qhov hydrogen embrittlement rhiab heev. Qhov no yog lub tswv yim yooj yim uas yuav tsum tau qhia meej los ntawm cov kws kho mob saum npoo av thaum sau cov txheej txheem electroplating specifications. Cov hlau uas muaj zog tensile σb> 105kg / mm2 xav tau los ntawm cov qauv thoob ntiaj teb yuav tsum raug rau kev nyuaj siab ua ntej plating thiab tom qab plating dehydrogenation kho raws li. Fabkis txoj kev lag luam aviation xav tau kev kho dehydrogenation sib xws rau cov khoom steel nrog cov khoom muaj zog σs> 90kg / mm2.

Vim qhov kev sib raug zoo ntawm steel lub zog thiab hardness, nws yog ntau intuitive thiab yooj yim rau txiav txim lub hydrogen embrittlement rhiab heev ntawm cov khoom los ntawm hardness dua los ntawm lub zog. Vim tias cov khoom zoo meej kos duab thiab cov txheej txheem machining yuav tsum tau cim nrog steel hardness. Hauv electroplating, peb pom tias hardness ntawm hlau nyob ib ncig ntawm HRC38 pib qhia qhov kev pheej hmoo ntawm hydrogen embrittlement puas. Rau qhov chaw siab dua HRC43, dehydrogenation yuav tsum tau txiav txim siab tom qab plating. Thaum lub hardness yog hais txog HRC60, kev kho dehydrogenation yuav tsum tau nqa tawm tam sim ntawd tom qab kho deg, txwv tsis pub cov hlau qhov chaw yuav tawg nyob rau hauv ob peb teev.

Ntim

Hais txog peb

* Daim duab hauv qab no qhia txog qhov sib txawv ntawm kev lag luam incoterms. Thov xaiv qhov koj nyiam.

KUB-muag khoom

Zoo Ua Ntej, Kev Nyab Xeeb Kev Nyab Xeeb